In today’s increasingly electrified world, reliable power distribution is critical to supporting everything from basic infrastructure to advanced technologies and urban developments. This means that every component of an electrical system is critical and must be protected from problems and outages.

Electrical power systems can also present risks to personnel and to the public. Today we will look at one component that plays a vital role in maintaining both the reliability and the safety of electrical power distribution: substation circuit breakers.

What Are Substations and What Role Do They Play in Power Distribution?

Substations are essential nodes in our power transmission networks. They manage the flow of electricity from high-voltage transmission lines to the lower-voltage distribution lines that serve our homes, businesses, industrial facilities, transit systems, and more.

Without substations, efficient distribution of electricity across vast distances and variable load requirements would be impossible.

What Are Substation Circuit Breakers and Why Do They Matter?

As energy demands continue to grow across the country and the world, particularly with the rise of renewable energy and electrification, the role of circuit breakers becomes even more central to maintaining grid stability.

Substation circuit breakers are vital components within electrical substations, tasked with protecting the entire system by detecting and isolating electrical faults. Their primary role is to “break” the circuit, interrupting current flow when an abnormal or dangerous situation, such as a short circuit, is detected. This protection ensures the integrity of the power supply system, minimizes damage to equipment, keeps people safe, and reduces the duration of power outages.

In other words, circuit breakers are vital to the safety, reliability, and continuity of power distribution networks.

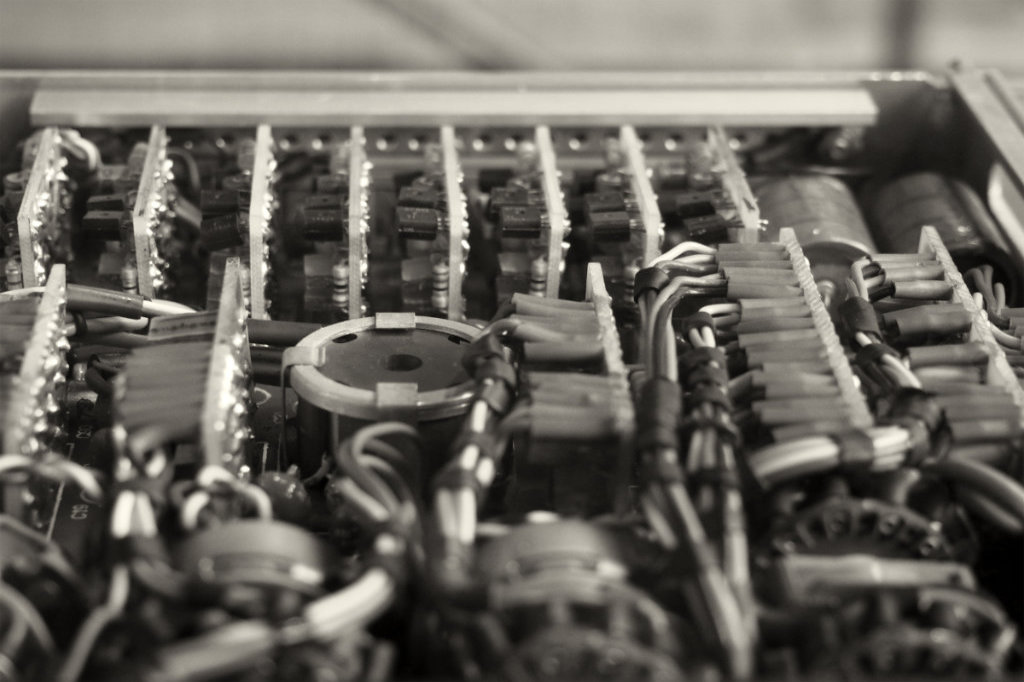

Defining Circuit Breakers in the Context of Substations

Circuit breakers are specialized switches designed to detect faults and stop the flow of electricity in high-stakes environments. In substations, they are configured to handle higher voltages and currents than those of household breakers. They play a pivotal role in protecting the grid.

A substation circuit breaker is tasked with isolating sections of the power grid when faults or abnormal conditions are detected. This isolation prevents potential damage to transformers, cables, and other critical infrastructure, maintaining the integrity of the power grid and enhancing safety for both network personnel and the public.

Types of Circuit Breakers Used in Substations

There are four main types of circuit breakers that are commonly used in electrical substations:

Air Circuit Breakers

These breakers use air as the dielectric medium to extinguish an electrical arc. They are commonly used in low-voltage applications but are also an increasingly versatile choice for specific high-voltage requirements.

Vacuum Circuit Breakers

Known for their efficiency in medium-voltage applications, vacuum circuit breakers extinguish arcs by separating contacts within a vacuum chamber.

Oil Circuit Breakers

In oil circuit breakers, oil-filled chambers absorb the arc energy, cooling and insulating the breakers to enable safe current interruption.

SF6 Gas Circuit Breakers

These breakers use sulfur hexafluoride (SF6) gas, which has high dielectric strength. This makes them effective for very high-voltage applications. They are highly reliable and require minimal maintenance.

The Critical Function of Circuit Breakers in Grid Reliability

Circuit breakers act as “guardians” of an entire grid. When a fault occurs, they react instantly to isolate the affected area, preventing widespread damage and minimizing power outages. This quick response is essential in preserving grid stability and reducing the risk of cascading failures, which could impact vast areas if left unchecked.

By investing in quality components, utility companies can mitigate risks, enhance service reliability, and support the growing demands of the modern grid.

Here at MAC Products, we understand that dependable circuit breakers are a cornerstone of resilient electrical infrastructure. That is why we emphasize quality and reliability in the breakers we produce and supply.

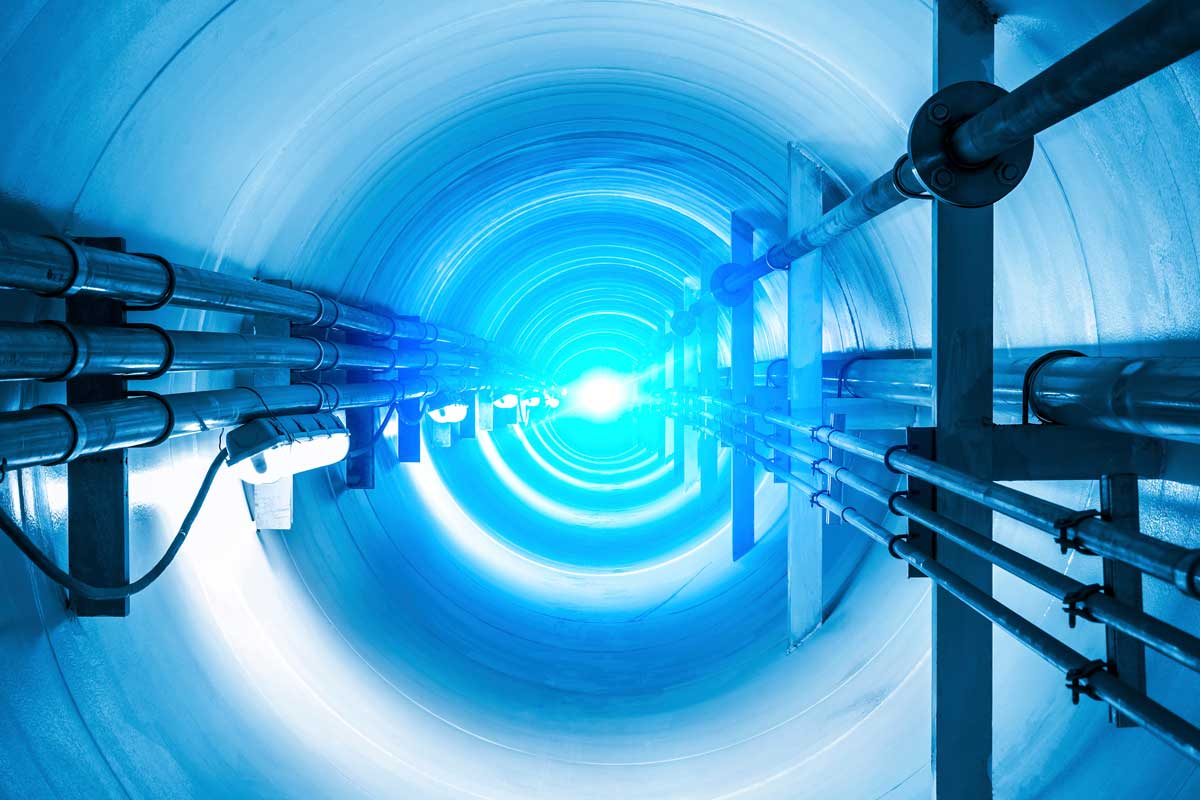

DC Switchgear in Electrical Substations

DC switchgear is a key component of electrical power control and distribution systems, such as those used in mass electrified transit systems. It is used within substations and onboard rolling stock (trains or other vehicles) to safely and efficiently convert power to the required voltage and current levels. In the context of a rail system, it converts high-voltage AC power from the main grid to low-voltage DC power.

Direct current (DC) switchgear is preferable to its alternating current (AC) counterpart for use in transit systems, as it offers greater control over functions such as speed and braking. It is also more efficient over long distances. However, many electrical systems will use AC and DC switchgear in combination.

Here at MAC, we have over five decades of experience working with DC traction systems and products, including our custom DC switchgear solutions for unique systems with complex requirements. To learn more about DC switchgear and our products, please read our recent blog post on this subject.

Substation circuit breakers are one important part of DC switchgear systems.

Key Features and Specifications of Substation Circuit Breakers

Substation circuit breakers are specialized pieces of equipment with specific and exacting requirements. In this section, we will look at their key features and the specifications they must meet.

Essential Specifications for High-Performance Substation Circuit Breakers

Circuit breakers are rated based on the maximum current and voltage they can safely interrupt. Selecting the right rating is crucial to ensure breakers can handle the appropriate system loads without compromising safety or effectiveness.

Interruption capacity is also crucial. This refers to the maximum fault current a breaker can interrupt without failing. A high interruption capacity is essential for substations serving densely populated or high-demand areas.

Finally, it is important to choose the correct insulation type for a given application. The different insulation methods we discussed above—air, vacuum, oil, or SF6 gas—protect breakers from arc flash and prolong their operational life.

At MAC, we have applied our extensive knowledge to design breakers that are configured for optimal performance in their intended environments.

Reliability and Safety Standards

Substation circuit breakers must comply with national and international reliability and safety standards, such as those set out by the American National Standards Institute (ANSI) or the International Electrotechnical Commission (IEC).

Compliance with these standards guarantees that the breakers meet at least the baseline requirements for both performance and safety.

All MAC Products breakers meet or exceed these standards, providing our clients with peace of mind and security in the knowledge that their equipment is safe and optimized for long-term performance in critical environments.

Durability in Harsh Environments

Substation circuit breakers are often exposed to harsh conditions, including extreme weather, dust, moisture, and temperature fluctuations. Their design must accommodate these conditions in order to maintain function and reliability.

At MAC, we utilize advanced manufacturing techniques and rigorous quality control procedures to ensure that our circuit breakers are built to withstand these challenging environments. All of our breakers undergo stringent testing to verify their durability and long-term reliability, even in the harshest outdoor settings.

How Substation Circuit Breakers Work—A Technical Overview

In this section, we will take a brief look at the technical aspects of substation circuit breakers to help you understand how they work.

Mechanisms of Action

Substation circuit breakers detect abnormal current flow, then signal an automatic mechanism to open the circuit and stop electricity flow. This rapid response protects transformers, substations, and downstream equipment from power surges and electrical faults.

The exact mechanism of their operation varies by breaker type. For example, air and vacuum breakers physically separate contacts, while SF6 gas breakers use pressurized gas to cool and interrupt the power arc.

Arc Quenching Techniques

When circuit breakers open to stop current flow, an electrical arc forms between the contacts. Arc quenching extinguishes this arc, preventing overheating and mitigating further damage. Various arc quenching techniques exist, including using compressed air, oil, or gas. Which one is used will depend on the breaker type.

At MAC, we are committed to incorporating advanced arc quenching methods in our circuit breaker designs to ensure high performance and longevity.

Technology That Enhances Breaker Functionality

Modern circuit breakers incorporate advanced materials and electronic systems to improve their response times and enhance their durability. Computerized monitoring, for example, allows breakers to detect faults with high precision and respond far more quickly than traditional breakers can.

We leverage state-of-the-art technology in design and manufacturing processes, ensuring that each MAC Product breaker performs optimally and meets evolving demands.

The Life Cycle of a Substation Circuit Breaker

A substation circuit breaker has three critical life stages: initial installation, maintenance and testing, and end-of-life. Following proper procedures at all of these stages will extend the life and enhance the efficacy of your circuit breakers.

Installation

Proper installation is crucial to ensure that your substation circuit breakers operate efficiently and reliably. Even the best breakers can underperform or fail if they are incorrectly installed.

Our MAC field service teams are highly trained in installation and commissioning, bringing years of experience to ensure a seamless setup. Their knowledge and expertise help utility companies to avoid issues and maximize the lifespan of their equipment.

Maintenance and Testing

Regular maintenance is essential to prolong the life of a circuit breaker. Routine inspections, cleaning, and component testing can help to identify wear and tear and resolve small problems before they become major issues.

At MAC Products, we support our clients with comprehensive testing services through our QCA lab, ensuring that all products meet strict quality standards. This includes real-time production monitoring and data sharing, allowing for transparent communication on performance and reliability.

End-of-Life and Replacement

Circuit breakers are designed to last a long time, typically 20 to 40 years. However, over time, even the most durable circuit breakers reach the end of their life cycle. Various factors, from environmental challenges to maintenance practices, can determine how long a breaker will last.

A circuit breaker coming to the end of its life will often be signaled by consistent maintenance needs, decreased performance, or an inability to meet newer grid demands.

At MAC Products, we are proud to offer replacement and upgrade solutions to ensure that our clients have access to the latest technologies, maintaining optimal grid performance and minimizing downtime when their circuit breakers must be replaced.

MAC Products’ Commitment to Quality and Reliability

At MAC Products, we are deeply invested in producing top-quality substation components, ensuring that our clients—from electric utility companies to transportation systems—have access to dependable and resilient infrastructure.

Drawing on over 50 years of experience, the MAC team combines skilled craftsmanship with advanced technologies to support the safety and efficiency of power distribution systems, meeting both current and future demands.

Why Quality Matters in Circuit Breaker Production

High-quality circuit breakers are fundamental to maintaining a stable power supply. They minimize power interruptions, protect infrastructure, and ensure safety. MAC’s integrated quality control, including a QCA lab with advanced measuring and testing equipment, ensures that every circuit breaker we produce is of the highest quality.

Advanced Engineering and Design Capabilities

The MAC engineering team specializes in cutting-edge designs, ensuring that each circuit breaker is optimized for specific grid applications. Our combined expertise spans mechanical, electrical, and electronic engineering, allowing them to meet diverse client needs.

With state-of-the-art manufacturing facilities and a team of skilled technicians and craftspeople, MAC delivers custom solutions that align with customer needs and exceed industry standards every time.

Customer-Centric Solutions for Diverse Applications

At MAC, our dedication to client satisfaction is reflected in our versatile solutions, which serve various power grid demands, from busy urban areas to remote regions.

The MAC approach ensures that each of our products is designed to meet the unique requirements of its application, reinforcing our commitment to delivering reliability and excellence across the electrical utility and transit sectors.

Learn More and Get in Touch

To learn more about anything we have discussed in this post, discover our range of circuit breaker solutions, or discuss your project needs, please contact us. A member of our team will be happy to help.