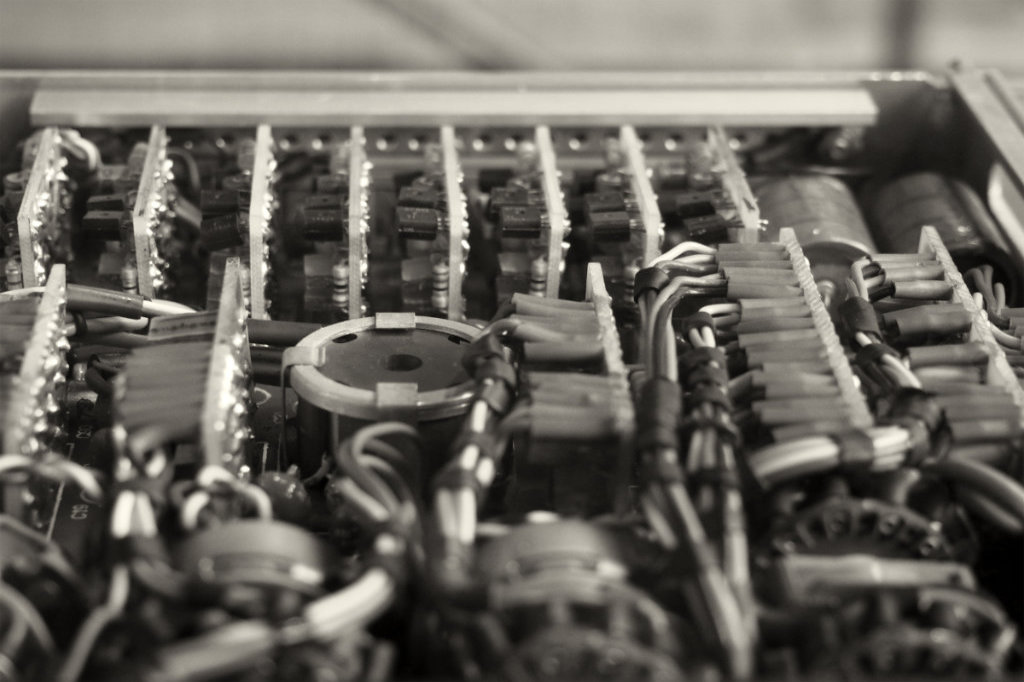

Sometimes, components of any electrical system need to be replaced. When sourcing replacement parts, there are two main options: original equipment manufacturer (OEM) and aftermarket parts.

Contrary to popular belief, there is no simple answer to whether OEM or aftermarket components are a better choice. This decision depends on numerous factors. In this post, we will focus on the key differences between OEM and aftermarket parts, the pros and cons of each, and how choosing the right parts can allow businesses to enhance productivity, reduce downtime, and boost efficiency.

What Are Original Equipment Manufacturer (OEM) Electrical Components?

Original Equipment Manufacturer (OEM) parts are those produced by or for the same company that made the original product or equipment. These items are usually sold through dealerships or authorized distributors.

A common example of OEM components is those found in cars. When a car needs repairing, the owner may choose to go back to the manufacturer or a licensed dealership that uses original parts rather than to a mechanic who uses third-party components. Similarly, an airline that needs to source a replacement part from an airplane may return to the company that manufactured the plane.

Pros

One significant advantage of original equipment manufacturer parts is their guaranteed compatibility. This means there is no risk of the part not performing as needed, reducing costly downtime and ensuring prompt repairs.

OEM electric components also offer reliable performance and guaranteed high quality. In addition, they often come with a manufacturer's warranty, providing peace of mind.

Cons

OEM parts usually cost more than their aftermarket alternatives. They may also be limited in availability for older model products. In addition, OEM parts may not be suitable for specialty needs or niche use cases.

What Are Aftermarket Electrical Components?

Aftermarket electrical components are those made by third-party companies that are not affiliated with the original equipment manufacturer.

For example, if a vehicle owner takes their car to a mechanic who does not use official parts sourced from the car's manufacturer, these parts are considered "aftermarket." Aftermarket parts are available from various suppliers, and their quality can vary significantly.

Original equipment manufacturers often warn that using non-OEM components can void the warranty on their products, leaving the owner liable for any problems.

Pros

Aftermarket parts tend to be more affordable than their OEM counterparts. They may also be more readily available, as aftermarket suppliers tend to keep more extensive inventory in stock than original equipment manufacturers.

Aftermarket parts can also be tremendously valuable when installed equipment needs to be serviced after many years. In these cases, the OEM may no longer exist or may no longer supply parts for that product. Aftermarket parts ensure that the entire item or system does not need to be replaced.

In addition, aftermarket manufacturers may be better placed to supply bespoke solutions such as performance and specialty parts. They may also offer better customer service and support.

Cons

Because aftermarket parts are not designed to meet the original equipment manufacturer's standards, their quality and reliability can vary significantly. There may also be compatibility concerns, as it can be challenging to be sure that aftermarket parts will work as intended.

In some circumstances, aftermarket parts can also void warranties. This can be costly if a problem occurs during installation or later.

Key Factors to Consider When Choosing Between Aftermarket and OEM Electric Components

In this section, we will look at some of the main factors to consider when choosing between OEM and aftermarket replacement electrical parts.

Equipment Age and Warranty Status

Newer equipment still under the original equipment manufacturer's warranty may benefit from OEM parts to protect the warranty. On the other hand, choosing aftermarket items for older or out-of-warranty equipment can be an effective way to save money.

Budget Constraints

Aftermarket parts may be more cost-effective for repairs of older equipment models.

If you are choosing aftermarket parts to save money, select a reputable US-based company that has been in business for a long time. Ensure the aftermarket brand provides a comparable or better warranty for its parts than the OEM supplier.

All MAC products come with a warranty, giving our customers the win-win of competitive pricing and peace of mind.

Performance Requirements

OEM parts are the best solution if you need to meet a reliable and consistent performance standard. On the other hand, if you are seeking specific upgrades or custom solutions, aftermarket parts are more likely to be suitable.

Aftermarket parts can also give you more flexibility. OEMs may require you to buy a large number of parts or not allow you to buy a single unit. In contrast, aftermarket brands can offer a customized solution for your unique design specifications or quantity needs.

Availability and Urgency

Because aftermarket providers often keep more inventory in stock, aftermarket parts can be more readily available in emergency situations.

Common Myths and Misconceptions

There are several common myths and misconceptions about original equipment manufacturers and aftermarket parts. In this section, we will dispel some of the most common.

"Aftermarket is always lower quality."

This is simply untrue. Aftermarket items can be of just as high a standard as their original equipment manufacturer counterparts, and aftermarket providers may be able to provide greater flexibility, custom solutions, and better customer support.

"OEM is always better."

While OEM can be a better choice in some circumstances, this is not always true. Depending on your needs, either option can be the right choice.

"You'll void your warranty if you use aftermarket parts."

Some manufacturers require original parts to be used to maintain their warranty, but this is not always true. Always check your warranty documents and read the fine print before deciding.

Recommendations for Different Scenarios

In the electrical industry, interchangeability or interoperability between manufacturers' products does not always exist. For example, a Siemens breaker will not work inside a GE panel. This means there are certain situations where staying with the original equipment manufacturer is advisable or essential. If in doubt, always check your equipment and the replacement electrical part for compatibility before you buy.

On the other hand, when machining or welding is involved in the repair process, aftermarket parts can usually be used as long as their form, fit, and function are suitable. This allows the equipment owner to save money by seeking an aftermarket solution.

MAC Products: Your Preferred Supplier of US-Made Replacement Electrical Parts

Both OEM and aftermarket electrical parts have pros and cons, and you will need to decide which is right for you based on your specific needs, priorities, and resources. If you have any doubts, always consult a trusted expert or parts expert for tailored advice.

Here at MAC, we are proud to support both scenarios. As an original equipment manufacturer, we supply official parts to fit our own products. However, we also support clients who approach us for aftermarket parts to fit equipment from out-of-business OEM companies.

Regardless of whether we are supplying OEM or aftermarket parts, customer service is tremendously important to us. When a customer needs help or can't find a solution, we are here to step in and help. We aim to reduce your downtime, enhance your productivity, and provide the right solution for your needs every time.