As technology continues to advance, the ways we work continue to change. New innovations bring new opportunities as well as new challenges, and businesses must remain agile and on top of technological developments to stay competitive in today’s market.

In particular, advances in technology have allowed for many aspects of manufacturing processes to be automated. In today’s article, we will take a close look at one example of a new technology that is revolutionizing the ways manufacturing businesses operate: cobots.

What Are Cobots, and How Are They Different From Robots?

The term “cobot” means “collaborative robot.” Cobots are specifically designed with human-robot interaction in mind and to work alongside humans.

The first cobot was invented by J. Edward Colgate and Michael Peshkin, professors at Northwestern University, in 1996. In recent years, the technology has advanced significantly and cobots are now used in numerous applications across many different industries. They are currently used particularly in Europe, though the United States is catching up.

A cobot is collaborative with its environment, allowing humans to work around and alongside it without the need for additional safety features. Ordinary robots will simply move where they need to without interruption and, because of this, may be situated behind a barrier or equipped with sensors to avoid causing harm to human workers. A cobot, however, is designed with safe interaction with humans in mind.

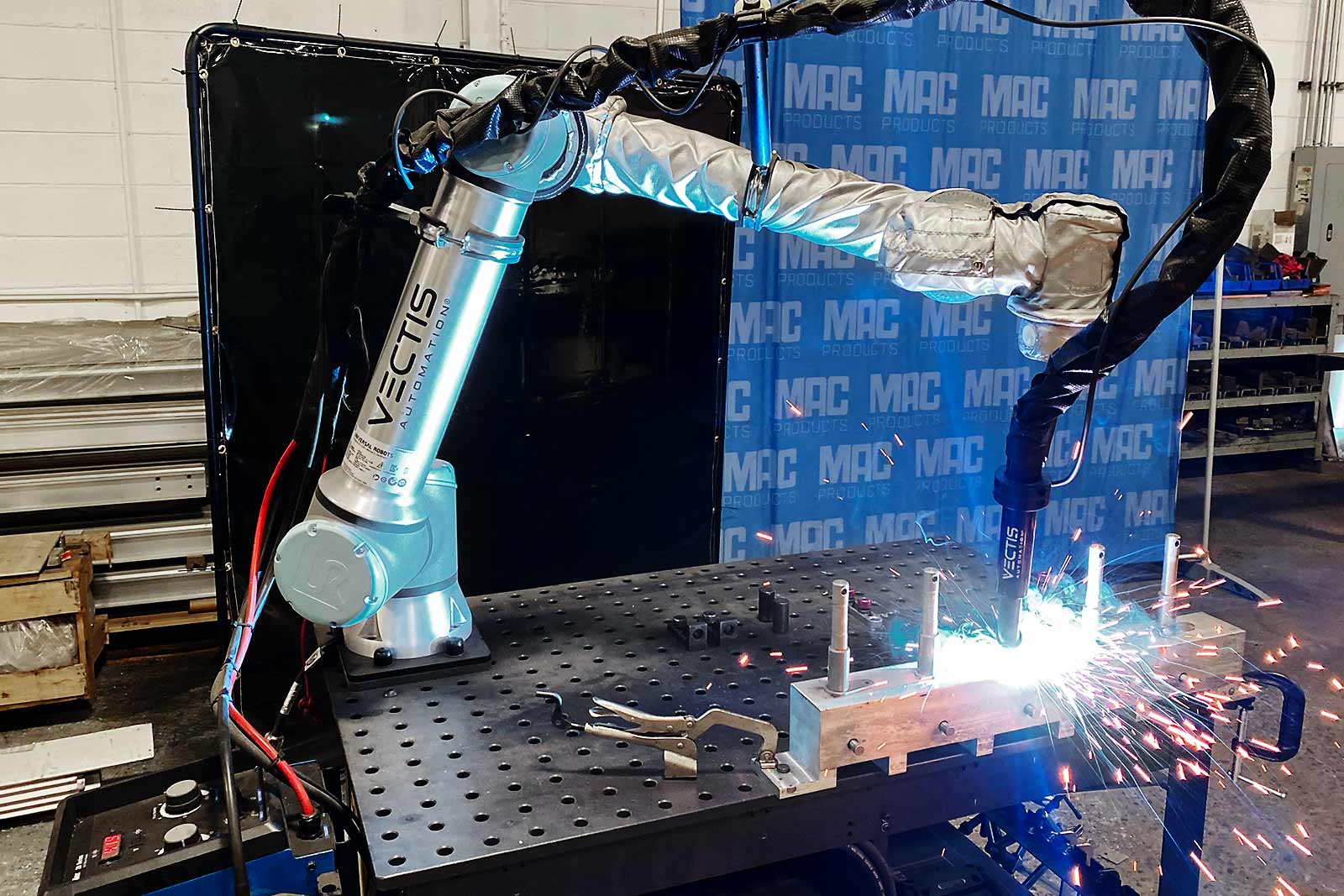

Cobots come in various sizes. Those we use here at MAC Products have a reach of around 50 feet and are capable of lifting up to 20 pounds. The cobot’s six joints allow for rotation in any direction, and many different tools—such as a gripper, welder, or screwdriver—can be placed on the end of its arm, depending on the task it needs to carry out.

Cobots do not tend to be mobile by themselves, but it is possible to move them to different locations manually or to set up systems to move them around as required. For example, we have a mobile welding unit using a cobot, a welder, and a movable table. All components are affixed on one mobile unit that can be used wherever the project is located or in our central welding area.

What Benefits Can Cobots Bring to Energy and Transit Manufacturing?

Here at MAC, our custom fabrication workshops tend to operate on a “high mix, low volume” basis. This means we make numerous parts and components, typically in small quantities. Cobots are able to switch between different tasks quickly just by changing the program, facilitating the easy manufacture of many different items.

It is important to note that cobots are not a replacement for human workers. Instead, they work alongside them, carrying out the simple and repetitive tasks to free up our human team members for the more complex work that they do best. We believe in investing in the education and growth of our people, offering them further training and career development opportunities. Cobots free up time and capacity for this to happen.

Cobots also allow for operations to continue overnight when no human workers are on site. For example, we are currently using a cobot to carry out machine-tending tasks during the night. This greatly increases overall productivity.

Cobots are significantly more user-friendly than traditional industrial robots, as minimal coding or programming knowledge is needed to work with them.

What Are the Best Ways to Use Cobots?

There are nearly endless ways to use cobots alongside your human workforce. The only “best” way to use them is the way that makes the most sense for your business and delivers the results you require. The only significant constraints cobots have are the reach of their arms and the amount of weight they can lift. Ultimately, their application depends upon your people and the ideas they bring to the table.

One of the reasons we believe cobots are such fantastic additions to the manufacturing industry is that they are so flexible. We believe in thinking outside the box and turning our creativity to the tools we have at hand, thinking of different ways to use our cobots and exploring the full extent of their capabilities for our industry.

Are There Any Applications in Which Cobots Don’t Work Well?

A cobot can be a valuable addition to virtually any manufacturing or industrial environment that is sufficiently open-minded to the possibilities they represent.

It is important to remember that cobots are tools; that is, they are inanimate objects to which we can apply our creativity and ideas to get results. The reason we see such success with the use of advanced technologies, including cobots, is because of our people.

How Does the Rise of AI Impact Cobots?

Artificial intelligence (AI) has grown tremendously in recent years and continues to enjoy further advancements all the time. When we purchased our first cobot (around five years ago), the user interface was far more complex than the cobots we are seeing today. These new iterations feature incredibly simple, push-button technology and English language instruction inputs. This means anyone on our manufacturing floor can comfortably use them with minimal training, usually within days.

In short, the rise of AI has made cobots more collaborative and more user-friendly. Many cobot companies now market their products as “plug and play right out of the box,” insinuating that the buyer can begin using the cobot within hours. This is closer and closer to becoming the norm and, eventually, this setup time and learning curve may be reduced to just minutes.

Some cobots are now able to take a picture of an object, determine the program they need to carry out the task at hand, and then select the relevant part needed automatically. This dramatically reduces the need for human intervention and represents a tremendous leap forward in cobot AI.

What Is the Future of Cobots?

Given their flexibility and many applications, we believe cobots will become more ubiquitous in the manufacturing industry and beyond. Here at MAC, for example, we currently use cobots primarily for welding and machine tending. In the future, we intend to expand into using them for assembly and bin-picking tasks.

As cobots become more affordable and easier to use, they will become accessible to smaller businesses and may even eventually find their way into our homes. Imagine having a small robot on your desk that could, for example, pick up your phone and hold it up for you each time it rings. With cobot technology, this is a very real possibility in the not-too-distant future.

As AI continues to become more advanced, cobot technology will also develop, and these machines will become capable of carrying out more and more tasks with less requirement for human workers to train or program them.

Learn More About Our Services

Here at MAC, we are proud to be using cutting-edge technology, including cobots, to continue providing the stellar service and high quality of work our clients expect.

If you would like to learn more about any of our product or service offerings, we would love to hear from you. Please contact us at any time, and a member of our team will be pleased to assist you in any way they can.